LC1 Type high current Three Phase Electrical Magnetic AC Contactor

- LC1 Type high current Three Phase Electrical Magnetic AC Contactor is suitable for using in the circuits to the rated voltage 380V AC 50/60Hz, current 800A, for long distance breaking circuit and frequently staring or controling the motor. It also can be send for the control of distributions circuits of rated current from 115A to 800A. It conforms to IEC60947-4-1.

- Technical parameters for magnetic ac contactor

| Model | Confroming to GB14048.4 standard | CJX2-F700 | CJX2-F850 | CJX2-F1050 | CJX2-F1300 | |

| Environment | ||||||

| Rated insulation voltage(Ui) | V | 1000 | 1000 | 1000 | 1000 | |

| Rated Impulse withstand voltage(Ue) | KV | 8 | 8 | 8 | 8 | |

| Rated operational voltage (Ue) | V | 1000 | 1000 | 1000 | 1000 | |

| Operational Power frequency range | HZ 16-----200 | |||||

| Standards | GB14048, IEC60947, EN60947 | |||||

| Ambient air temprature | storage | ℃ | -60--+80 | |||

| running | ℃ | -5---+55 | ||||

| under rated voltage | ℃ | -40--+70 | ||||

| Maximum operating altitude | m | 2000 | ||||

| permitted altitude | m | 2000 | ||||

| Humidity | + 40℃ relative humidity less than 50%, below 40 ℃ maximum humidity less than 90% |

|||||

| Impulse withstand capacity 1/2 sinewave=11ms | contactor opening | 6gn | 6gn | 6gn | 6gn | |

| contactor closing | 15gn | 15gn | 15gn | 15gn | ||

| Shock and vibration resistance…150Hz | contactor opening | 1.5gn | 2gn | 2gn | 2gn | |

| contactor closing | 5gn | 4gn | 4gn | 4gn | ||

| Degree of pollution | Pollution degree III | |||||

| Protection degree | Main circuit | IP00 | ||||

| coil terminal | IP20 avoid direct contact with the finger | |||||

| Operating frequency | cycles/hour | 600 | 600 | 600 | 600 | |

| Operating position | without derating | ±300 ( in relation to normal mounting plane) | ||||

| Control circuit characteristics (rated control voltage) | AC | V | 110-660 | |||

| DC | 110-500 | |||||

| control voltage limits (≤55℃) | Operating voltage | V | 0.85-1.1Uc | |||

| Drop-out voltage(AC) | V | 0.2-0.75Uc | ||||

| Drop-out voltage(DC) | V | 0.1-0.75Uc | ||||

| Average consumption | Inrush (AC) | VA | 1150 | 1150 | 1730 | 1730 |

| Sealer (AC) | VA | 18 | 20 | 25 | 25 | |

| Inrush (DC) | W | 1140 | 1220 | 1920 | 1920 | |

| Sealer (DC) | W | 7.5 | 8 | 12.5 | 12.5 | |

| Operating time | closing | ms | 40-75 | |||

| opening(AC) | ms | 100-170 | ||||

| opening(DC) | ms | 45-60 | ||||

| Mechanical durability (under Uc) | 106 | 3 | 3 | 3 | 3 | 3 |

| Notes: for other installation methods, does not guarantee the contactor related performance | ||||||

| CJX2-F1450 | CJX2-F1700 | CJX2-F2100 | CJX2-F2600 | CJX2-F3200 |

| 1000 | 1000 | 1000 | 1000 | 1000 |

| 8 | 8 | 8 | 8 | 8 |

| 1000 | 1000 | 1000 | 1000 | 1000 |

| Maximum relative humidity less than 90% below 20℃ | ||||

| 6gn | 6gn | 6gn | 6gn | 6gn |

| 15gn | 15gn | 15gn | 15gn | 15gn |

| 2gn | 2gn | 2gn | 2gn | 2gn |

| 4gn | 4gn | 4gn | 4gn | 4gn |

| 600 | 600 | 600 | 600 | 600 |

| 2200 | 2200 | 2200 | 3000 | 3000 |

| 40 | 40 | 40 | 50 | 50 |

| 2200 | 2200 | 2200 | 3000 | 3000 |

| 16 | 16 | 16 | 20 | 20 |

| 3 | 3 | 3 | 2 | 2 |

| CJX2-F1450 | CJX2-F1700 | CJX2-F2100 | CJX2-F2600 | CJX2-F3200 |

| 1450 | 1700 | 2100 | 2600 | 3200 |

| 1000 | 1000 | 1000 | 1000 | 1000 |

| 16-200 | 16-200 | 16-200 | 16-200 | 16-200 |

| 1450 | 1700 | 2100 | 2600 | 3200 |

| 2175 | 2550 | 3150 | 3900 | 4800 |

| 9000 | 10000 | 11500 | 13000 | 14800 |

| 6800 | 7500 | 8500 | 9950 | 11000 |

| 4900 | 5500 | 6400 | 7700 | 8950 |

| 3700 | 4200 | 4800 | 5800 | 6900 |

| 2700 | 3000 | 3600 | 4260 | 5400 |

| 2 | 2 | 2 | 3 | 3 |

| 0.083 | 0.071 | 0.057 | 0.046 | 0.037 |

| 175 | 205 | 250 | 310 | 380 |

| 2 | 3 | 4 | 3 | 3 |

| 100X5 | 100X5 | 100X5 | 100X10 | 100X10 |

| 4-12 | 4-12 | 4-12 | 4-12 | 4-12 |

| 58 | 58 | 58 | 58 | 58 |

- Application

Used in circuit of AC 50/60Hz, voltage up to 1000V ,current up to 3200A, controlling resistance , noninductive, slightly inductive loads, distribution circuits

| Rated operational current A | Le AC1 (Ue 380V) | 700 | 850 | 1050 | 1300 |

| Conventional thermal current A | Ith =40℃ (Ue 380V) | 700 | 850 | 1050 | 1300 |

| Rated operational voltage (Ue)max | Max | 1000 | 1000 | 1000 | 1000 |

| Number of poles(NO) | 2\3 | 2\3 | 2\3 | 2\3 | |

| Maximum operating power KW 3-phases ≤40℃ AC1,50Hz | 220/240V | 240 | 295 | 360 | 450 |

| 380/400V | 420 | 510 | 630 | 780 | |

| 440V | 470 | 570 | 700 | 870 | |

| 500V | 520 | 630 | 780 | 960 | |

| 660/690V | 685 | 830 | 1030 | 1270 | |

| 1000V | 1035 | 1260 | 1550 | 1920 | |

| Short-circuit protection by fuse Type "2" | type | RSG-3 | RSG-3 | RSG-3 | RSG-3 |

| specification | 1100 | 1100 | 1100 | 1100 | |

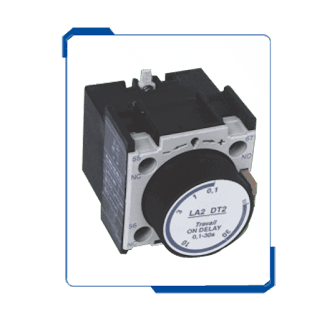

| Optional parts | Instantaneous auxiliary contact: ZTCF3\ Time delay auxiliary contact: ZYCST\ZTCSR protection from dust /mosit: LADX |

||||

| Contactor | CJX2-F700 | CJX2-F850 | CJX2-F1050 | CJX2-F1300 | |

| Weight(Kg) | 8.9 | 11.7 | 17.3 | 18.6 | |

| Serial number | 3-poles | 1041 | 0142 | 0143 | 0144 |

| 2-poles | 0146 | 0147 | 0148 | 0149 | |

| 1450 | 1750 | 2100 | 2600 | 1450 |

| 1450 | 1700 | 2100 | 2600 | 1450 |

| 1000 | 1000 | 1000 | 1000 | 1000 |

| 2\3 | 2\3 | 2\3 | 2\3 | 2\3 |

| 500 | 585 | 730 | 870 | 500 |

| 870 | 1000 | 1250 | 1500 | 870 |

| 980 | 1150 | 1400 | 1690 | 980 |

| 1080 | 1250 | 1550 | 1860 | 1080 |

| 1430 | 1650 | 2050 | 2460 | 1430 |

| 2150 | 2500 | 3100 | 3720 | 23150 |

| RSG-3 | RSG-5 | RSG-5 | RSG-6 | RSG-6 |

| 1500 | 2000 | 2300 | 2800 | 3200 |

| CJX2-F1450 | CJX2-F1700 | CJX2-F2000 | CJX2-F2600 | CJX2-F3200 |

| 26.7 | 27.7 | 32.2 | 32.2 | 51 |

| 0127 | 0126 | 0130 | 0130 | 0131 |

| 0135 | 0136 | 0138 | 0138 | 0139 |

- Ploe Characteristics

| Type | CJX2-F700 | CJX2-F850 | CJX2-F1050 | CJX2-F1300 | ||

| Rated operational current A Ue≤ 400V | AC1 | A | 700 | 850 | 1050 | 1300 |

| Rated operational voltage Ue | Max | V | 1000 | 1000 | 1000 | 1000 |

| Frequency limits | of the operation current | Hz | 16-200 | 16-200 | 16-200 | 16-200 |

| Conventional thermal current | ≤ 40℃ | A | 700 | 850 | 1050 | 1300 |

| Making capacity | 1 rms conforming GB14048.4 | A | 1050 | 1275 | 1575 | 1950 |

| Breaking capacity | A | Turn on the breaking current 1.5X1 (AC1) | ||||

| Short-ciruit rating cold state ≤ 40℃ | 10 secs | A | 4200 | 5100 | 6300 | 7800 |

| 30 secs | A | 3360 | 4080 | 5040 | 6240 | |

| 1 min | A | 2100 | 2550 | 3150 | 3900 | |

| 3 min | A | 1680 | 2040 | 2520 | 3120 | |

| 10 min | A | 1260 | 1530 | 1890 | 2340 | |

| Each paralle out numbers | 2 | 2 | 2 | 2 | ||

| Average impdeance per pole | MQ | 0.17 | 0.14 | 0.12 | 0.096 | |

| Power dissipation per pole for the above operational currents | AC1(Ue≤ 400V) | W | 85 | 100 | 120 | 150 |

| Wiring can match wire cut off | number of bars | 2 | 2 | 2 | 2 | |

| dimensions of bars | mm2 | 50X5 | 50X5 | 80X5 | 100X5 | |

| bolts diameter | Number -Φ | mm | 1-12 | 1-12 | 3-12 | 3-12 |

| Tightenning torque | circuit connection | N.m | 58 | 58 | 58 | 58 |

- 3-pole interlocked contactors(vertical mounting)

| Contactors | Rated operational current AC1 A | Maximum operational power AC1 3 phases W | Weight (Kg) | Serail Number | |||

| CJX2-F | 220V | 380V | 660V | without bar | with bar | without bar | |

| 1000Lc | 1000 | 350 | 600 | 980 | 41 | 50 | 0475 |

| 1250Lc | 1250 | 430 | 750 | 1230 | 43 | 54 | 0476 |

| 1450Lc | 1450 | 500 | 870 | 1430 | 55 | 68 | 0477 |

| 1700Lc | 1700 | 585 | 1000 | 1650 | 59 | 74 | 0478 |

| 2100Lc | 2100 | 730 | 1250 | 2050 | 63 | 80 | 0479 |

| 2600Lc | 2600 | 870 | 1500 | 2460 | 83 | 106 | 0480 |

| 3200Lc | 3200 | 1090 | 1890 | 3100 | 103 | 138 | 0481 |

- Schematic diagram

- Vertrical mounting 3-pole interlocked contactor components

| Product model | Contactors | Interlock Model | Mounting bar Model | Fitting model | |

| CJX2-F | Inter-locking | vertical fitting bar | horizontal fitting bar | ||

| 1000Lc | 1000L (2uits) | ZRJSA | ZRDL10088 | ZTJG9743 | ZTJG9743 |

| 1250Lc | 1250L (2uits) | ZRJSA | ZRDL12588 | ZTJG9743 | ZTJG9743 |

| 1450Lc | 1450L (2uits) | ZRJSA | ZRDL14588 | ZTJG9743 | ZTJG9743 |

| 1700Lc | 1700L (2uits) | ZRJSA | ZRDL17088 | ZTJG9743 | ZTJG9743 |

| 2100Lc | 2100L (2uits) | ZRJSA | ZRDL21088 | ZTJG9743 | ZTJG9743 |

| 2600Lc | 2600L (2uits) | ZRJSA | ZRDL26088 | ZTJG9767 | ZTJG9736 |

| 3200Lc | 3200L (2uits) | ZRJSA | ZRDL32088 | ZTJG9767 | ZTJG9736 |

1. Components are set t ohave center to center distance of 580mm by default

2. Optional defualt components have center to center distance of 580mm

3. Not part of products, supply along with products, need to be installed by users. Contactors could be fixed on two vertical fitting bars(100-2100Lc) or three vertical bars (2600-3200Lc) or four horizontal fittings bars before final installation, or contactors could be fixed directly on fitting rack withou fitting bars

|

|

|

|

|

|

|

|

|

Comments

Post a Comment